Capabilities

- Home

- Capabilities

Ampmil Interconnect team got rich experience and expertise in Mil-grade connector domain, able to design and deliver custom connector solutions with high precision manufacturing and ontime delivery.

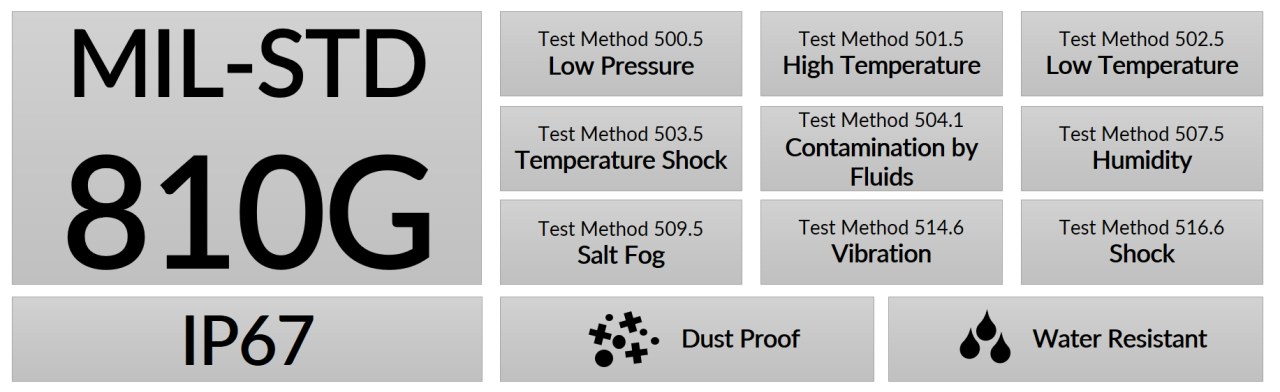

Ampmil Interconnect products are subjected to MIL-STD-810 Testing as per application need

Ampmil Interconnect has adopted data management systems for product data traceability purpose. Each component data recorded systematically on cloud server.Any point of time required data can be accessed from the database.

We are working with high precision Tool & Die makers, capable of building any kind of specialized tooling for our products, such as Plastic Injection Molds, Transfer Molds, Rubber Molds, High precision micro sheet metal stamping, Jigs & Fixture, Stage Inspection Gauges, Specialized micro assembly toolings. etc.

Ampmil Interconnect equipped with high precision CNC machining facility to manufacture highly complex components with global quality ASME Y14.5 GD&T standards. We have policy of using reliable standard cutting tools to ensure the consistency in every piece we produce. Majority of our parts finished on 4-axis CNC machining so that multi parts mating references are achieved with zero deviation.

_1745561744.png)